In a lot of ways, Eagle is very much the younger sibling. It seems that it wants to have done to it whatever I've finished doing with the Gremlin. Ignition, front bearings, ball joints, and today it looks like it wants leaf springs. Checking out the rear leads to investigate a popping sound revealed that the leafs are shot. I mean, flat as a board. Zero arch, and I'm not posting a picture because I don't want to legitimize the condition.

Back to Gremlin.

Not a lot got done today. Most of what was done centered around checking gasket inventory and fitment, though the timing chain cover was removed once I figured out a way to relocate the AC compressor without venting the system. This allowed me to pressure wash the timing cover, replacement oil pan, and valve cover in preparation of painting them all with a nice new coat of AMC blue. I'll get as much paint down tonight as I'm able, then tomorrow it's off to the yard to take advantage of a 50% off all parts deal.

Looking for a power steering pump bracket, maybe a backup radiator. If I'm feeling fancy, I might check for hand-me-down leafs. Eagle has to be in Eastern Washington near the end of September for a thing I'll mention later, and these leafs won't cut it. I'm hoping like hell that the Gremlin will make it as well, though that remains to be seen.

Wednesday, August 30, 2017

Eagle Happenings

Experience has shown me that slapping an HEI distributor and a Weber carb on an Eagle can get you a 100mph+ wagon. Experience has also shown me that, just because you can do something, doesn't mean you should. At least not without making sure that the plastic valve cover doesn't start spraying oil when the engine is running that hard, getting it all over the choke wire, and setting off an interesting chain of events.

I was about 90 miles outside of town and with a tank dangerously near empty at the time I pulled over. After idling for about 5 minutes, Eagle died and the cab started filling up with that rich smokey smell we all love. A couple moments were spent trying to find the fire extinguisher under my trash cache and old car parts before I decided opening the hood to battle the apparent fire in the engine bay might be the least stupid decision over hoping things would just take care of themselves.

|

| Carburetor? Damn near killed 'er! |

Even though doing this is always the wrong decision, I went ahead with it and found a fire hot enough to get the hood insulation burning was uncomfortably close to the carburetor. Close to, meaning, actively burning the choke cover and cap on the neighboring vacuum port.

In case you don't know, a burning carburetor isn't something you want to have. Especially when you've been driving hot and sucking nothing but vapor from the fuel tank.

Luckily, the fire was in check after I made a wish and blew everything out. I took an old vacuum line, fed the now-naked choke wire through, loosely zip tied it to stuff to keep it clear of the manifold, and re-capped the now open vacuum port. Fired right up. I plugged the hole over the choke cover while Eagle was idling and heard no change in the motor, so I guess I somehow managed to avoid getting a vacuum leak. That being said, a new cover and a carb rebuild is in the cards for sure.

There's not really a lesson here, except that having an inaccessible fire extinguisher is worth as much as not having having one at all. Oh. . . Now I remember where it is; I left it over at my friend's house a while back during some welding work. Huh.

Monday, August 28, 2017

Hello morning

Right hub pin (pictured on the left) didn't have a dust shield when I bought Eagle. I would've figured that it would've been the one to go to hell first, all other variables being the same. Not so. It was the left hub (picture right) that was deciding to go it's separate ways when I started this. Now it's just getting this mess in and torqued to spec in time to join the Seattle commuter rush hour(s) after my 24 hours of tears.

24/7 the thunder will roll

Sunday, August 27, 2017

Got my bearings now, so I'm pressed for success with a seal of approval.

After spending two days fighting a fastener, I finally got to the point where I could begin pressing Eagle's bearings into the hubs. It was pretty great until I discovered I was two seals short of being able to finish. At 9:30PM on a Sunday.

Luckily, there's an AutoZone in Tacoma that's 24 hours. Seriously. Even more luckily, they had the seals I needed. Beyond even more luckily, the friend who's been kind enough to help with this mess while my car has been stuck in his driveway also let me use his car to run down there from Seattle to get the last two seals that were in stock.

Once I arrived, life gave me a nice illustration of exactly how important this work is (aside from the fact that the hub started separating when I was pulling into the driveway to begin this stuff on Friday).

Luckily, there's an AutoZone in Tacoma that's 24 hours. Seriously. Even more luckily, they had the seals I needed. Beyond even more luckily, the friend who's been kind enough to help with this mess while my car has been stuck in his driveway also let me use his car to run down there from Seattle to get the last two seals that were in stock.

Once I arrived, life gave me a nice illustration of exactly how important this work is (aside from the fact that the hub started separating when I was pulling into the driveway to begin this stuff on Friday).

A Grand Cherokee, even. Note the rotor scrapes in the parking lot surface. Those went all the way out to the street. Alright. Back to Seattle to get this stuff wrapped up so I can get back to work.

Saturday, August 26, 2017

Burton Kozak: Inhuman monster.

Gremlin efforts are stalled as I attend to the ball joints and hubs on the Eagle. If I could, I'd continue ignoring them and go about my planned work, but I guess other drivers expect ALL the wheels of your vehicle to stay on ALL the time that you're driving.

Lucky for me, 90% of what I'm doing is exactly like the Gremlin, part for part. The remainder, however. . .

I'd like some explanation as to why the assembly most-often exposed to harsh conditions that result in rusted fasteners (if not more) is assembled with GODDAMNED EXTERNAL TORX bolts. Not only that, but fine pitched. Not only that, but 1-3/4” long. Not only that, but thread locked to hell all the way down. So, my work continues today.

I guess things could be worse, though.

https://docs.google.com/viewer?url=patentimages.storage.googleapis.com/pdfs/US7073416.pdf

Lucky for me, 90% of what I'm doing is exactly like the Gremlin, part for part. The remainder, however. . .

I'd like some explanation as to why the assembly most-often exposed to harsh conditions that result in rusted fasteners (if not more) is assembled with GODDAMNED EXTERNAL TORX bolts. Not only that, but fine pitched. Not only that, but 1-3/4” long. Not only that, but thread locked to hell all the way down. So, my work continues today.

I guess things could be worse, though.

https://docs.google.com/viewer?url=patentimages.storage.googleapis.com/pdfs/US7073416.pdf

Thursday, August 24, 2017

Don't worry about me. I got a coupon.

Take this as another in the endless stream of examples of how you cause yourself far more frustration, upset, difficulty, and work by trying to employ workarounds, rather than cutting to the chase and using the correct damn tool that the job called for in the first place.

As last night wore on, I kept trying to find ways to cope with my lack of a proper means to raise my block. After trapping a ratchet boxend on a bolt for a motor mount bracket, and teaching a hard stop two bolts short of freeing the oil pan, I called it quits and decided that the next day would begin with me putting an end to this shit and getting ahold of a hoist.

Pictured above is the straw that stuck the camel with a huge medical bill and months of physical therapy. It's tough to make out, but blue is oil pan, and the brownish rust-colored part that bends over the pan flange is the bottom of the motor mount bracket.

For reasons I can only assume are tied to maintaining the fuckery index value of doing an otherwise simple job, this seemingly superfluous portion of the bracket appears to have the sole function of blocking access to two bolts that couple the pan flange to the block. All the other bolts, naturally, are a breeze to reach.

So this morning I checked Craigslist, found no ads that were worth the time and money, looked at tool rental outfits nearby and laughed at the $40+/day rental rates they were charging, and then looked at the coupons page for our go-to importer of tools and flashlights. This netted me a new hoist for less than people were charging for their used ones that were an hour out of town.

Time to max my pump and swell my thick. By the way: fingers are still dyed.

As last night wore on, I kept trying to find ways to cope with my lack of a proper means to raise my block. After trapping a ratchet boxend on a bolt for a motor mount bracket, and teaching a hard stop two bolts short of freeing the oil pan, I called it quits and decided that the next day would begin with me putting an end to this shit and getting ahold of a hoist.

Pictured above is the straw that stuck the camel with a huge medical bill and months of physical therapy. It's tough to make out, but blue is oil pan, and the brownish rust-colored part that bends over the pan flange is the bottom of the motor mount bracket.

For reasons I can only assume are tied to maintaining the fuckery index value of doing an otherwise simple job, this seemingly superfluous portion of the bracket appears to have the sole function of blocking access to two bolts that couple the pan flange to the block. All the other bolts, naturally, are a breeze to reach.

So this morning I checked Craigslist, found no ads that were worth the time and money, looked at tool rental outfits nearby and laughed at the $40+/day rental rates they were charging, and then looked at the coupons page for our go-to importer of tools and flashlights. This netted me a new hoist for less than people were charging for their used ones that were an hour out of town.

Time to max my pump and swell my thick. By the way: fingers are still dyed.

Wednesday, August 23, 2017

Strike a prose

A motor mount has been replaced,

The deck has been cleaned,

Mostly.

The oil pan is half unbolted,

The harmonic balancer is pulled,

The timing cover remains.

I've done half of many things.

The deck has been cleaned,

Mostly.

The oil pan is half unbolted,

The harmonic balancer is pulled,

The timing cover remains.

I've done half of many things.

Pardon the stall in updates. Temporary case of the deads. Vital functions restored, so we'll see how this round goes.

But I'm back at it now. Here's a helpful hint: harbor freight mechanics gloves are most-easily differentiated by the ways each type will allow you to sustain injury. The red and black, knuckle-types have very meltable fingertips. If you try and half-assedly apply a lesson learned and get the "leather" ones, don't use B-12 while you have them on. Effects can include mild chemical burns, tattooing. From 08/20, date of discovery:

And as of today, 08/23.

Three days, four showers, and at least one gojo application occurred within this time. I'm considering doing the other hand. Like a dear friend said, "symmetry is key!"

More substantial updates to come. Engine work is ongoing, tedious. Damn oil pan.

And as of today, 08/23.

Three days, four showers, and at least one gojo application occurred within this time. I'm considering doing the other hand. Like a dear friend said, "symmetry is key!"

More substantial updates to come. Engine work is ongoing, tedious. Damn oil pan.

Sunday, August 20, 2017

Still rooting around in the brains

Combustion chambers are nice and tidy now. Gonna get to lapping the valves and such today. Using the old valves since it turns out I didn't order new valves after all.

The block is getting the gasket remains cleaned off. Long and slow work. Between the chemical parade involved in cleaning this and the head, I think I'm finally starting to win my war against my brain.

Since there's not a whole lot to share as an update, here's a picture of the first specialty tool I'd mentioned in use:

Back to the solvent box.

Friday, August 18, 2017

Off with it's head

Receiving some much-appreciated help from my friend allowed me to remove the old head without suffering loss of life or lumbar. Check out this decapitated 258:

All in all, we're not looking like we're too bad off. There's some slight marring of some of the cylinder walls, but nothing worrisome. The biggest problem that we saw was the stop leak used by the previous owner appears to have been used less as an aid to address a leaking heater core, and more of a fix for a leaking head gasket.

The pushrod chamber walls are lined with crusty garbage that the stop leak bound to when entering this area through the gaps where the gasket wasn't sealing. I'm optimistic and think that this is localized to that part of the block. I've changed the oil in this a few times over the years, and while the first change was a little gross, the later changes were fairly clean. We'll see after the pan comes off in the next day or two. Right now I'm building an equivalent of another specialty tool:

All in all, we're not looking like we're too bad off. There's some slight marring of some of the cylinder walls, but nothing worrisome. The biggest problem that we saw was the stop leak used by the previous owner appears to have been used less as an aid to address a leaking heater core, and more of a fix for a leaking head gasket.

The pushrod chamber walls are lined with crusty garbage that the stop leak bound to when entering this area through the gaps where the gasket wasn't sealing. I'm optimistic and think that this is localized to that part of the block. I've changed the oil in this a few times over the years, and while the first change was a little gross, the later changes were fairly clean. We'll see after the pan comes off in the next day or two. Right now I'm building an equivalent of another specialty tool:

Thursday, August 17, 2017

No Rest for the Obsessed

Front end's done. Both sides. Correctly (I mean, at least as far as I know). I didn't have time to paint the steering and suspension components, so they got a healthy dose of grease. This was totally intentional and not at all a combination of my lack of time to paint all that the proper way and grease getting every fucking place imaginable. Here's a shot of the passenger side, followed by it's partner:

I also removed the valve cover bolts in preparation of removing the head. Time for engine bay days after I get done pretending to sleep. This motor only has 100k on it, but I'm still getting the same kind of sweats as I get about 8 hours after a 7-11 burrito. We'll see whether this is omen or bad diet soon enough.

Tuesday, August 15, 2017

Breathe Grease

Bearings are fun if you like to get grease all over every surface within the walls you're surrounded by. I knew I should've got that bearing packer.

Anyway, we're still suspended. For some reason or another, installing the driver's side coil spring turned out to be an ungodly pain in the ass. The difficulty was largely from the upper control arm being disagreeable, but I can't help but suspect that the whole thing would've been over in less than 6 hours if I had pulled the head and manifolds prior to taking this on (left the garage at 05:00 because I heard the morning traffic beginning at 04:30).

The biggest issue was, as always, clearance. The orientation of the bolts are pointed outward, that is, the bolt heads are closer to the center of the shock tower, while the nut for each is closer to the firewall and radiator, respectively. This centerline is also where the EGR valve hangs out, while the A/C, wiper fluid, and. . . something else run through in parallel to the steering column. I ended up taking off the EGR valve, which made life a little more worth living.

Driver's side should be all set momentarily, though that's subject to change because the lower control arm is taking a cue from it's upstairs neighbor and is being a pain in my ass. After that, I get to take the passenger side back off to address a fitment issue with the strut rod. See, when installing the lower ball joint, I put the boot and retainer on in the order that was seen on the old one. Turns out that wasn't the correct thing to do, which serves as a reminder that you should never assume that the last person to work on something had any more clue about what they were doing than you do.

Sunday, August 13, 2017

If you can ear me, here's a tip:

If you're like me, you probably find that you often fail to plan or fail to act. Sometimes both in equal measure. That means you might overlook doing something that would certainly be in your best interest, like performing any level of cleaning to the underside of a vehicle before beginning extensive work underneath it.

The next time you're under the car banging on shit and causing several decades of road grit to fall directly into your ear, remember the used nitriles that litter your work area like the autumn leaves once blanketed (or maybe still do) your project car. At least one finger of one of these little guys is clean after having been turned inside-out, which makes it a perfect impromptu ear plug once it's been freed from the rest of the glove. As for the eyes, I dunno. . . Blink faster or something.

The next time you're under the car banging on shit and causing several decades of road grit to fall directly into your ear, remember the used nitriles that litter your work area like the autumn leaves once blanketed (or maybe still do) your project car. At least one finger of one of these little guys is clean after having been turned inside-out, which makes it a perfect impromptu ear plug once it's been freed from the rest of the glove. As for the eyes, I dunno. . . Blink faster or something.

Friday, August 11, 2017

Where am I doing here?

While I smoke, I figure it's a good time to get an idea of what to do next in place. The biggest hurdle to overcome in my shop is the finite space available to work in, since it's a very single car garage with a ton of steel in the middle of the floor. The rafters aren't exactly what I'd call stout, so there's a lot of material taking up floor space that would normally be stowed up above, such as:

- Eagle wheels and snow tires (x4)

- A904 transmission cores (x2)

- Gremlin door (x2)

- Gremlin fender (x2)

- Gremlin hood

- Old leaf springs

- More

Keep in mind I'm doing more than just routine part replacement within the garage space. I'm also doing caveman machining, torch work, painting, and poorly-executed welding. It's safe to say that every square inch of the shop would give an OSHA inspector night terrors if they had reason to review it. Long/short: shit needs to be tidied up.

Old parts can be collected in a scrap metal pile, which is going to grate on my sense of "don't throw that away! You can use it for something!" like you wouldn't believe. I asked the transmission shop if they'd be interested in the 904s, and they would- for free. I know I got more than my $100 worth out of them, but I'd rather give them to someone that would use them with their AMC. Not so much interested in giving someone two cores that they can invest a couple hundred in each and then resell for a few grand in all.

Car work that's still needed:

- Motor mounts

- Install transmission

- Bend and run cooler lines

- Same for fuel lines

- Pull old head, intake and exhaust manifolds

- Rebuild new head

- Install new head

- Cut and braze intake to accept carb plate (throttle body seat dimensions are all wrong)

- Install intake, headers

- Oil pan, may as well do the pump while I'm in there

- Timing gear/chain

- Install wiring

- Replace power steering pump and high pressure line

- Rotorhubs and brakes

- Finish rebuilding heater box

- Drop in new heater core

- Torque suspension fasteners to spec once (nearly) full running weight is in place

- Body work: minor patches to driver/passenger floor pans, cowl, rear fenders

- Install replacement doors

- Get windshield installed

- Get exhaust work done at Shoreline Muffler if they're down. I'd read online that a dude took his Rambler American in for them to run dual side exhaust from his I6 with header, and the body is fairly similar. Probably should give them a call once I'm closer to that point.

- Get alignment

- Paint touch ups

- Cut new vinyl hockey stripes (white as before, but the new ones will glow in the dark)

- Clear coat

- Hillbilly undercoat (oil and dirt)

I'm screwed.

I'll figure out what I'm going to do next, then make space accordingly. Probably toss up a Craigslist ad after pulling the stuff in the engine bay and give away the head, manifolds, and transmissions. Time to rock.

Very good. Now: Repeat it.

|

| "Gremlins wear boots, yeah, ya gotta believe me. . . " |

Correction to the post prior to the last: you don't install the coil before the upper control arm. Instead, bolt your coil seat/saddle/perch/foot/base/whateverthehell to the upper control arm and lift it into place by compressing the spring. While doing so, prepare for the very enjoyable and not at all terrifying experience of beating the hell out of that arm to get the pivot bolt holes to line up with the holes in the shock tower while the spring is still cranked down.

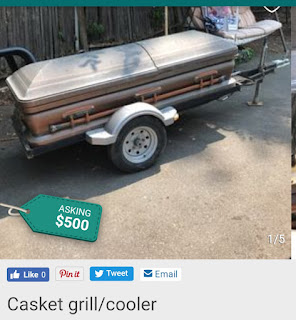

I also saw this, and were it not for the fact that it lacks title and inspection (which I don't have time or want to spend the money to pursue), it would have been refit to serve as my pull-behind sleeping quarters. I would've been a spectacular Dracula.

Thursday, August 10, 2017

So nice, I'm posting twice

My last post may have been a little misleading, since it might have given the impression that I'd actually followed through and completed the coil installation.

Unfortunately, I forgot that I'd cut my coil compressor too short to release safely ["That's what she said!" jokes will meet the same fate as Wayne's World posts. -ed]. Actually, it'd probably be more accurate to say that I didn't put two and two together to realize that the short rod wouldn't do the job for putting it back in [Seriously. Don't do it. -ed]. So tomorrow is "go to the hardware store to unfuck what you done fucked" time. And here I was thinking I'd only have to do that once this week. . .

Since a good portion of tomorrow will be more of today, I figured I'd toss up some observations that may be useful. You might have noticed (though I don't blame you if you didn't) that I detailed all the tool sizes for the transmission removal, but not the suspension. You'd be partly right to assume that this was due to equal measures laziness and shitty brains, but the bigger reason is because I realized that cataloging and listing that info was being done more as an aid to procrastinate than anything else. Granted, the info about the top three bolts would've helped me if I had it in advance, but that's not the same as doing a fastener inventory. In summary, some reference material is more time-consuming to source and review than it would be to just do the damn thing you've set out to do in the first place.

That said, there's still an alternative to the two methods most-often used to identify tool sizes, which are to memorize to 1/16 what a given size looks to be (impractical for me at either ends of the range of commonly-encountered fasteners) or to put a damn socket on it over and over again until you find the right one. The answer is to always have these two quad-box ends with you. The ratchet is just hanging out because it's been as much or more valuable as a timesaver as these guys.

Solid gold. That's 8 sizes in two wrenches that are able to get on 90% of the fasteners I've encountered. The other 10% have been close enough to figure out, or had a neighbor of the same size that could be checked. Beats the hell out of running squat thrust drills back and forth to the workbench, or digging around in the bottomless socket sack (or it's cousin, the library of blow-molded cases).

In case you suspect that I'm acting as a shill, note that I haven't written out any brand names. To be honest, I could care less what brand you get (or even if you take my advice to begin with). Far as I know, though, only one company makes the red feller. Which reminds me:

Why isn't there such a thing as a battery-powered die grinder? I don't mean a rotary tool; I want my "60V" angle grinder without a 90° gearbox, but the closest you can get is a sheetrock cutter. Not the same thing.

Alright. I'm done.

Unfortunately, I forgot that I'd cut my coil compressor too short to release safely ["That's what she said!" jokes will meet the same fate as Wayne's World posts. -ed]. Actually, it'd probably be more accurate to say that I didn't put two and two together to realize that the short rod wouldn't do the job for putting it back in [Seriously. Don't do it. -ed]. So tomorrow is "go to the hardware store to unfuck what you done fucked" time. And here I was thinking I'd only have to do that once this week. . .

Since a good portion of tomorrow will be more of today, I figured I'd toss up some observations that may be useful. You might have noticed (though I don't blame you if you didn't) that I detailed all the tool sizes for the transmission removal, but not the suspension. You'd be partly right to assume that this was due to equal measures laziness and shitty brains, but the bigger reason is because I realized that cataloging and listing that info was being done more as an aid to procrastinate than anything else. Granted, the info about the top three bolts would've helped me if I had it in advance, but that's not the same as doing a fastener inventory. In summary, some reference material is more time-consuming to source and review than it would be to just do the damn thing you've set out to do in the first place.

|

| Don't Think. Chances are you're not smart enough to do it correctly. |

That said, there's still an alternative to the two methods most-often used to identify tool sizes, which are to memorize to 1/16 what a given size looks to be (impractical for me at either ends of the range of commonly-encountered fasteners) or to put a damn socket on it over and over again until you find the right one. The answer is to always have these two quad-box ends with you. The ratchet is just hanging out because it's been as much or more valuable as a timesaver as these guys.

Solid gold. That's 8 sizes in two wrenches that are able to get on 90% of the fasteners I've encountered. The other 10% have been close enough to figure out, or had a neighbor of the same size that could be checked. Beats the hell out of running squat thrust drills back and forth to the workbench, or digging around in the bottomless socket sack (or it's cousin, the library of blow-molded cases).

In case you suspect that I'm acting as a shill, note that I haven't written out any brand names. To be honest, I could care less what brand you get (or even if you take my advice to begin with). Far as I know, though, only one company makes the red feller. Which reminds me:

Why isn't there such a thing as a battery-powered die grinder? I don't mean a rotary tool; I want my "60V" angle grinder without a 90° gearbox, but the closest you can get is a sheetrock cutter. Not the same thing.

Alright. I'm done.

Wednesday, August 9, 2017

Okay, so to recap. . .

Notes on removal of the front suspension (vehicle already raised):

- Remove shock

- Weld together a tool of questionable integrity to compress your coil

- Remove suspension bumper stop

- Disconnect ball joint from upper control arm

- Swing lower suspension components out of the way

- Compress spring slightly so that you can unbolt spring seat

- Swing lower control arm down as far as you can (while performing 8)

- Grab that spring after compressing it the bare minimum needed to wrestle the bastard away from the upper control arm

- Get ready to pull the rotorhub and it's bearings

- Attempt to dislodge the outer races of the bearings from the rotorhub, while working diligently to ensure you ruin the latter

- Buy new bearings, races, seals, and of course, rotorhubs

Notes on putting all that crap back in:

- Rebush and install the upper control arm before anything else, while you still have all of the suspension components removed

- Reinstall all the other shit like an idiot, saving the coil and shock for last, because you really don't want to do the coil

- Attempt to reinstall coil (you don't have to spend much time performing this step before moving on to 4)

- Remove upper control arm

- Reattempt to reinstall coil

- After coil is seated in shock tower but still compressed, work in hurried terror to reinstall upper control arm

- Save the rotorhubs and bearings to get around to them when you feel like it

Monday, August 7, 2017

I'm Did Asbestos I Can!

Old cars, old wheel assembly dust, old problems.

No updates for the past few days, but I can't blame this on Eagle this time. After removing the coil, I set about getting the ball joints, tie rod, and control arm bushings taken care of. This all moved along fairly smoothly, until I reached what I'd presumed was the last step on this path: the lower ball joint.

Turns out I was approaching a new learning opportunity. See, servicing the lower control arm/ball joint requires removing the rotor and hub, which are cast as a single part. This means the wheel bearings gotta go as well. When I started to read this process in the service manual, my face probably changed to a subdivision living room shade of off-white because my mind immediately jumped to the same process as it applies to the Eagle (you can find the process online. To sum it up: not fun).

Luckily, despite the integration of components I'd prefer to be separate into a single assembly, AMC did a really good job of making the whole shebang really serviceable. I think this is the first time I've encountered a pleasant surprise like this. It also worked to my benefit, since I found that the bearings that felt fine were actually far from it and needed replacing. Better to learn that in the garage than in the middle of the desert somewhere, right?

Lastly, look who's back! Unfortunately, the planetary gearing upgrades I had discussed with the shop wouldn't fit, but it's got the valve body upgrades and new everything from stem to stern. I'm not sure whether I'm going to put it back in right away. Probably going to wrap up the front end first. Note the AMC-ish blue on the torque converter. So far, I'm pretty pleased with the work done (George's Transmission on Aurora in Seattle), and amazed that they got it done on the Friday following the Wednesday afternoon when I'd dropped it off.

Despite having taken an 18 hour nap, I'll probably tuck in for another 6 or so, then we're back at it. Later I'll get some pictures of the hub, knuckle, etc assembly for any who may be interested.

No updates for the past few days, but I can't blame this on Eagle this time. After removing the coil, I set about getting the ball joints, tie rod, and control arm bushings taken care of. This all moved along fairly smoothly, until I reached what I'd presumed was the last step on this path: the lower ball joint.

Turns out I was approaching a new learning opportunity. See, servicing the lower control arm/ball joint requires removing the rotor and hub, which are cast as a single part. This means the wheel bearings gotta go as well. When I started to read this process in the service manual, my face probably changed to a subdivision living room shade of off-white because my mind immediately jumped to the same process as it applies to the Eagle (you can find the process online. To sum it up: not fun).

Luckily, despite the integration of components I'd prefer to be separate into a single assembly, AMC did a really good job of making the whole shebang really serviceable. I think this is the first time I've encountered a pleasant surprise like this. It also worked to my benefit, since I found that the bearings that felt fine were actually far from it and needed replacing. Better to learn that in the garage than in the middle of the desert somewhere, right?

So here's our lower control arm bushing. Totally ruined. Good thing I decided against cutting corners on this mess. I'll say one thing about this bushing, the ones in the upper arm, and the one in the spring coil seat: burn the fuckers down. Get a torch and burn them all out. The accidental driveway did that I had are an optional practice, but they really help to keep you on your toes.

Lastly, look who's back! Unfortunately, the planetary gearing upgrades I had discussed with the shop wouldn't fit, but it's got the valve body upgrades and new everything from stem to stern. I'm not sure whether I'm going to put it back in right away. Probably going to wrap up the front end first. Note the AMC-ish blue on the torque converter. So far, I'm pretty pleased with the work done (George's Transmission on Aurora in Seattle), and amazed that they got it done on the Friday following the Wednesday afternoon when I'd dropped it off.

Despite having taken an 18 hour nap, I'll probably tuck in for another 6 or so, then we're back at it. Later I'll get some pictures of the hub, knuckle, etc assembly for any who may be interested.

Friday, August 4, 2017

Victory or die!

So I removed the shocks, as well as this.

After tempting fate with a pry bar and the broken coil spring, I made a coil compressor similar to what's described here:

https://www.hemmings.com/blog/index.php/2008/05/21/hmx-diy-coil-spring-compressor/

My thinking being that it would be a safer approach to use the already-existing components that have the job of keeping the coil contained.

Here it is in action during it's inaugural use on the unbroken spring:

Things got a little tense in the release phase. See, I cut the threaded rod so I could get a deep socket on the nut, totally overlooking the fact that I'd need some travel to release the spring safely.

A few cigarettes later, I decided that the coil couldn't be under much tension at that point. It was extended beyond the point it was at prior to compression, and the Gremlin was raised on the lift to let the suspension hang, so I decided I'd wrap the hell out of it with welding blankets and just keep backing that nut off. After another cigarette.

Afterwards, I went back in the garage and set to it, making every attempt to do a stupid thing in as smart as easy as possible.

As you can see, it worked out fine. The coil just dropped right out without leaping up to kill anything in it's path. It was a close shave, though, as the pull on the retaining hardware didn't begin to let up until the last 1/2 thread.

Terror wasn't the only result of the work, though. Here's what the control arm bushings are looking like. Now I can replace them and the mounting hardware with some new grade 8 fasteners.

The parts I pulled all went into the degreaser tub.

And I got a seat that's more comfortable than I'd expect.

Tomorrow it's ball joints and tie rod ends, then I'm taking it's brother out. I have to get a move on, since the transmission shop called today to get some more info on the application. They said they might have it ready tomorrow, but more likely the beginning of next week.

Thursday, August 3, 2017

I forgot to publish this with a title, now I'm coming up dry as I add one. Uhhh. . . Suspension stuff. There. That's all you're getting from me.

Okay, so now that we've uncovered the thing that's sure to be responsible for how I die, let's take a look at the condition of the rest of the suspension. I've taken pictures of the driver side components, which are probably slightly better off than the passenger side.

So the ball joints and motor mounts are done. That's about what I'd expected, so all's well on that front. I'll get pictures of the upper and lower control arm bushings once they're out, but I'll give you a hint as to how they look: god awful. Tie rod ends may as well get the hell out of there, too.

After finding the blown coil last night, I decided to pre-treat all the fasteners I'll be freeing with some slip sauce. Figured I'd also slather some on the head and manifold fasteners, too, despite that work not coming up for a while.

In case you're asking what that might be, here's your answer:

When I returned today, the shock tower fasteners wound out with next to no complaints. The shocks, however. . . Well, "shock". It seems that the shock that accompanies the popped coil has been doing the work of maintaining tension, so it complained rather sharply when I got the tower cap off. Nothing too bad; just slapped the inner fender panel and made me jump and cuss like Yosemite Sam.

I'm back at the house for a moment, but heading back to finish the job. If there are no more updates after this, send someone out to seek revenge on the coil that killed me. Also remember this: never trust honky teeth.

Wednesday, August 2, 2017

Suspension off disbelief and a cautionary tale

I chose the suspension.

Things appear to be in much better shape than expected, which is good. However, the fuckery balance must be maintained. . .

In my pre-work research, I came across something that I feel compelled to address. It is, hands down, the is the biggest recurring hurdle that I've had to overcome in my efforts battling entropy:

task and manufacturer-specific tooling.

These tools are not commonly accessible, are expensive, and usually serve only one purpose in addition to their engineered function: to take up space that you don't have to spare until the next time you need the tool. Not having them can make a couple hour job take days or longer, since you're now spending hours upon hours trying to find a source that will sell the tool at a price that won't send you to an even crappier poor house, eventually giving up, finding someone to borrow money from one last time (I swear!), and then waiting for UPS ground to get around to hanging a missed delivery notice on your door after they've broken the item while unloading the truck that's been sitting at their distribution center for two days.

After reviewing my service manual, I've found that I get to begin yet another iteration of this grueling process. In case you're curious, here's the tool in question:

UPDATE:

Shit.

Things appear to be in much better shape than expected, which is good. However, the fuckery balance must be maintained. . .

In my pre-work research, I came across something that I feel compelled to address. It is, hands down, the is the biggest recurring hurdle that I've had to overcome in my efforts battling entropy:

task and manufacturer-specific tooling.

These tools are not commonly accessible, are expensive, and usually serve only one purpose in addition to their engineered function: to take up space that you don't have to spare until the next time you need the tool. Not having them can make a couple hour job take days or longer, since you're now spending hours upon hours trying to find a source that will sell the tool at a price that won't send you to an even crappier poor house, eventually giving up, finding someone to borrow money from one last time (I swear!), and then waiting for UPS ground to get around to hanging a missed delivery notice on your door after they've broken the item while unloading the truck that's been sitting at their distribution center for two days.

After reviewing my service manual, I've found that I get to begin yet another iteration of this grueling process. In case you're curious, here's the tool in question:

UPDATE:

Shit.

Slow and steady wins the race. . .

Since I don't have a parking spot at my garage, and I prefer not to block the people I'm renting from into their driveway the day after I'm late paying my rent, getting the transmission to Eagle so that it could be hauled to the shop was a little more tedious than I'd expected.

Half a block down.

The rest to go.

Since the 904 is a fairly low-weight transmission (the housing is aluminum), the load wasn't cumbersome. The challenging part was making sure that I didn't move too quickly and cause the thing to be shaken off the hand truck as it rattled down the broken up, pebble-crete sidewalk.

About a block further and the slusher was loaded into the rock wagon. Took it straight to the transmission shop, who said it should be sorted out by the middle of next week or so. Now what the hell do I work on?

To do:

Half a block down.

The rest to go.

Since the 904 is a fairly low-weight transmission (the housing is aluminum), the load wasn't cumbersome. The challenging part was making sure that I didn't move too quickly and cause the thing to be shaken off the hand truck as it rattled down the broken up, pebble-crete sidewalk.

About a block further and the slusher was loaded into the rock wagon. Took it straight to the transmission shop, who said it should be sorted out by the middle of next week or so. Now what the hell do I work on?

To do:

- Front suspension

- Remove head, manifolds, install new (from 2003 4.0L)

- Install engine bay wiring

- Cut out rotted metal from cowl, patch, paint (in preparation of new windshield installation)

- New exhaust

- Tons of other shit that I'll remember later. Like body and interior work.

Tuesday, August 1, 2017

All my world's been colored green, on everything that I have seen - it's coolant

No updates the last couple days, partly on account of transmission research, partly due to garage clean ups, but mostly due to Eagle having a failed water pump (specifically, a worn out pulley bearing). I misinterpreted the symptom of coolant escaping the weep hole as coming from a bad hose seal, though eventually it got figured out.

Inspection of the engine bay and the pump itself led me to conclude that three different contributors caused the failure:

1) The fan clutch had worn out.

2) Alternator and power steering belts were over tightened.

3) The water pump was over 30 goddamned years old.

Thank you for your service, old water pump. Eagle and I salute you and your efforts.

Inspection of the engine bay and the pump itself led me to conclude that three different contributors caused the failure:

1) The fan clutch had worn out.

2) Alternator and power steering belts were over tightened.

3) The water pump was over 30 goddamned years old.

Thank you for your service, old water pump. Eagle and I salute you and your efforts.

Subscribe to:

Posts (Atom)